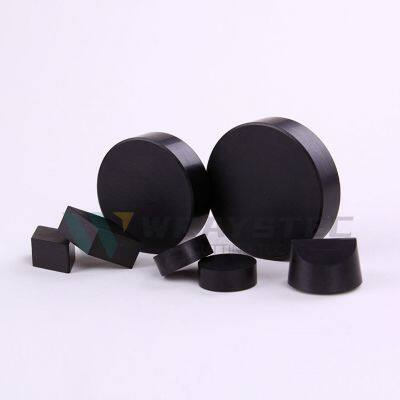

PCD inserts

1. What are PCD inserts?

PCD is the English abbreviation for Polycrystalline Diamond. PCD inserts refer to cutting tools that use polycrystalline diamond as the cutting edge.

Polycrystalline Diamond: It is not a natural single diamond crystal, but a solid block of polygonal composite material formed by sintering countless tiny artificial diamond micro-powders under extremely high temperature and pressure using a metal binder (such as cobalt). You can imagine it as a "high-strength mass of diamond particles bonded together with a metal binder."

Insert Structure: Typically, PCD material is not used to make the entire insert, but is welded onto a carbide tool body in the form of a tip or insert. This utilizes the ultra-hard and wear-resistant properties of PCD while reducing costs and ensuring the toughness of the tool body.

2. Main Characteristics of PCD Inserts

Advantages:

Extremely high hardness and wear resistance: Its hardness is second only to natural single-crystal diamond, and dozens of times harder than cemented carbide. This is its most outstanding advantage.

Low friction coefficient: It has low affinity with non-ferrous metals, making it less prone to built-up edge formation during machining, resulting in a high surface finish.

High thermal conductivity: It can quickly conduct cutting heat, reducing the temperature of the cutting edge.

Long lifespan: On suitable materials, its lifespan is dozens or even hundreds of times longer than cemented carbide tools, significantly reducing tool changes and improving automated machining efficiency.

Disadvantages:

Poor toughness and high brittleness: Sensitive to impact and vibration, not suitable for intermittent cutting or rough machining conditions.

Limited range of machinable materials: Primarily used for machining non-ferrous metals and non-metallic materials. Cannot machine ferrous metals (steel, cast iron, etc.) because diamond reacts chemically with iron at high temperatures (carbide formation), leading to rapid tool wear.

Difficult to manufacture and high cost: The manufacturing of PCD itself and the process of grinding it into a sharp cutting edge are complex, resulting in a higher initial purchase cost for the tool.

3. Main Application Areas (What materials can it machine?)

PCD inserts are the preferred cutting tools for machining the following materials:

Non-ferrous metals:

Silicon-aluminum alloys (especially those with high silicon content, such as engine pistons, cylinder heads, and wheel hubs): PCD inserts are the "king" for machining these materials, easily handling the hard silicon particles within them.

Copper and copper alloys, magnesium alloys, Babbitt metal, etc.

Hard and wear-resistant non-ferrous metals: such as tungsten-copper alloys, sintered tungsten carbide, etc.

Non-metallic materials:

Reinforced composite materials: such as carbon fiber reinforced plastics, glass fiber reinforced plastics, etc.

Ceramics, graphite, fiberglass.

Hard rubber, plastics.

Others: Hardwood, MDF, etc.

PCD (Polycrystalline Diamond) cutting tools are indispensable key tools in modern manufacturing, especially in the automotive, aerospace, and electronics industries, for the efficient, high-precision, and high-quality machining of non-ferrous metals. Although their initial purchase cost is relatively high, in suitable applications, their overall cost is more advantageous due to their exceptionally long service life and stable machining quality.

Recently Posted

-

How to choose the right carbide tools?

January 6, 2026Selecting the appropriate high-performance cemented carbide tools (such as milling cutters, turning inserts, and drill bits) is a Read More

Read More -

What is cemented carbide? What are its main uses?

January 5, 2026What is cemented carbide?Simply put, **cemented carbide is a composite material made from hard metal carbides and a binder metal t Read More

Read More -

What are electroplated diamond grinding heads and what are their uses?

January 5, 2026This is a detailed introduction to "electroplated diamond grinding heads," covering their definition, principle, charact Read More

Read More