What is cemented carbide? What are its main uses?

What is cemented carbide?

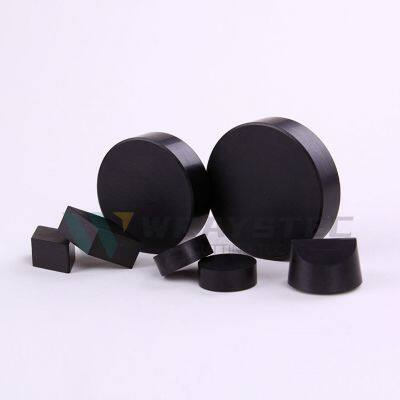

Simply put, **cemented carbide is a composite material made from hard metal carbides and a binder metal through powder metallurgy.** It is also known as "tungsten steel" (commonly referred to as such in China) or "tungsten carbide alloy."

Its core components are:

1. **Hard phase (providing hardness and wear resistance):** Primarily **tungsten carbide** particles. Tungsten carbide has extremely high hardness, second only to diamond, providing the alloy with excellent wear resistance and compressive strength.

2. **Binder phase (providing toughness):** Usually **cobalt**, sometimes nickel, iron, or other metals are also used. It "binds" the hard tungsten carbide particles together, giving the alloy a certain degree of toughness and preventing brittle fracture.

By changing the fineness of the tungsten carbide particles and the proportion of cobalt content, cemented carbides with different properties (hardness, toughness, wear resistance) can be produced to suit various application scenarios.

Outstanding characteristics of cemented carbide:

* **Extremely high hardness and wear resistance:** Maintains high hardness even at high temperatures (good red hardness), many times harder than steel.

* **Good compressive strength:** Can withstand enormous pressure without deformation.

* **Certain toughness:** Compared to ultra-hard materials such as ceramics, it has better toughness and is less prone to chipping.

* **Corrosion resistance and oxidation resistance:** Some grades of cemented carbide have good chemical stability.

* **Low thermal expansion coefficient:** Small dimensional changes with temperature, resulting in high stability.

---

Main Applications

With its excellent "hard but not brittle" properties, cemented carbide is known as the "teeth of industry" and is widely used in fields requiring high strength and high wear resistance:

1. Cutting Tools (largest application area)

* **Turning tools, milling cutters, drills, reamers:** Used for processing steel, cast iron, non-ferrous metals, stainless steel, etc., with efficiency and service life far exceeding high-speed steel tools.

* **CNC inserts:** The vast majority of indexable inserts used in modern machining centers are made of cemented carbide. 2. Molds and Wear-Resistant Parts

* **Wire Drawing Dies:** Critical molds for drawing metals (such as copper, aluminum, and steel) into fine wires, requiring extremely high wear resistance.

* **Cold Heading Dies, Stamping Dies:** Used for mass production of metal parts.

* **Rolling Mills:** Used for rolling wire or small profiles.

* **Sealing Rings, Bearings:** Wear-resistant components used in harsh working conditions.

3. Mining and Geological Tools

* **Rock Drilling Bits:** Drill bits, cutting teeth, etc., used in mining, oil drilling, and geological exploration. This is one of the earliest and most important applications of cemented carbide.

4. Wear-Resistant Parts and Structural Components

* **Nozzles:** High-pressure nozzles used for sandblasting and waterjet cutting.

* **Anvils and Punches:** High-pressure devices used for synthesizing superhard materials such as synthetic diamonds.

* **Columns, Guide Rails:** Precision mechanical components requiring extremely high wear resistance.

5. Everyday Applications

* **The "ball" of a ballpoint pen:** The most classic everyday application; the wear-resistant silver ball is made of cemented carbide.

* **Watch cases, high-end pen nibs:** Used to improve wear resistance and texture.

* **Cutting Tools:** The blades of some high-end kitchen knives or outdoor knives use cemented carbide to maintain sharpness.

Summary

**Cemented carbide is essentially a miraculous material that combines extremely hard tungsten carbide particles with a metal cobalt "glue," resulting in a material with both ultra-high hardness and appropriate toughness.** As a fundamental material in modern industry, it has greatly improved the efficiency and precision of machining, resource extraction, and equipment manufacturing, and is an indispensable key material for high-end manufacturing and heavy industry.

Recently Posted

-

How to choose the right carbide tools?

January 6, 2026Selecting the appropriate high-performance cemented carbide tools (such as milling cutters, turning inserts, and drill bits) is a Read More

Read More -

PCD inserts

January 6, 20261. What are PCD inserts?PCD is the English abbreviation for Polycrystalline Diamond. PCD inserts refer to cutting tools that use p Read More

Read More -

What are electroplated diamond grinding heads and what are their uses?

January 5, 2026This is a detailed introduction to "electroplated diamond grinding heads," covering their definition, principle, charact Read More

Read More